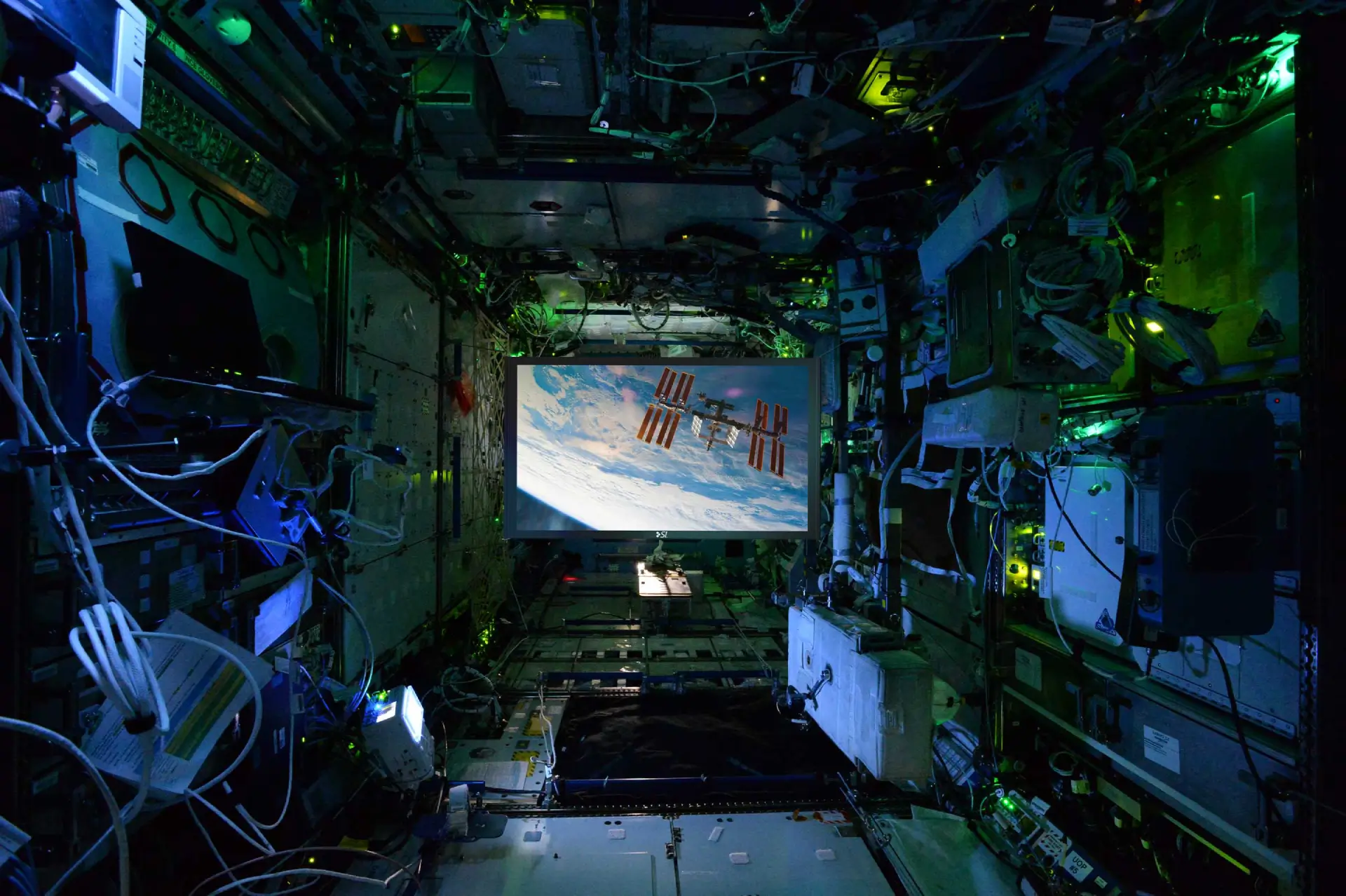

The National Aeronautics and Space Administration (NASA) recently asked Screen Innovations (SI) to do something that no other projection-screen company has done: put the first projection screen in space! Yes, you read that correctly. SI has developed a one-of-a-kind, ambient-light–rejecting, zero-gravity screen that is about to be installed in the International Space Station, to be used every day by astronauts and cosmonauts.

On March 27, 2015, one astronaut and one cosmonaut traveled to the International Space Station (ISS), where they will remain for a year while a team back on Earth studies the effects on them of long-term spaceflight. Because the astronaut is one of a pair of identical twins, this study will offer scientists a unique opportunity to establish a control, to achieve a far more accurate study of the effects of zero gravity on the human body.

Before installation of SI’s screen, the only form of communication available to astronauts on the ISS was via tablet-sized, 13-inch displays. As you can well imagine, the larger screen will allow crewmembers to experience images of their families that are closer to life-size, and to feel as if their loved ones are there with them in the cabin. Along with video chatting, the crew had also used small laptop computers for training and simulated operation of the ISS’s robotic arm. Obviously, the benefits of using these types of applications on a much larger screen are, literally, huge.

SI has always enjoyed a fun-loving company culture dedicated to constant innovation in screen technology and to pushing—and sometimes completely removing—the boundaries of two-piece projection. This made working with NASA a logical fit. Since its founding, in 1958, NASA has been devoted to innovation, and to pioneering the age of space travel and exploration. It’s safe to say that SI has once again gone where no other screen company has gone before.

Where do you even start?

In their eight months of work on the ISS project, the SI engineering team faced nonstop challenges, such as how to unroll and set up the screen as quickly as possible in zero gravity, and the fact that, in the ISS, the lights are always on—unlike a standard matte-white screen, SI’s screen material had to be able to preserve the projector’s contrast ratios. These challenges tested the team’s ability to deliver on a longtime SI motto: to provide “two-piece projection in any environment.” Ryan Gustafson, CEO of SI, said, “Space – it’s the ultimate environment. If we can put a screen there, we can put a screen anywhere on Earth.”

First, the ISS screen had to be constructed in such a way that it would be portable, and could be unrolled and made ready for viewing in seconds, in any module of the ISS. The screen also had to be easily packed away on the ISS – a permanently installed screen was not an option. “Fixed is easy, but a portable setup brings all sorts of challenges to the table,” said Tom Nugent, Technology Dealer at SI. Not only did the screen have to be portable, it had to be extremely portable. The final dimensions of the screen, when packed, could be no larger than those of a standard mailing tube for blueprints: roughly 3 feet long, with a diameter of 2½ inches. This immediately eliminated some screen materials – such as SI’s Black Diamond® and FlexGlass®, which can’t be tightly rolled – and left only a few remaining options.

Ever since the introduction, in 2008, of Black Diamond® – a still-unmatched technology that brought the industry to its feet – SI has had an authoritative presence in the ambient-light–rejection market. NASA had impeccable timing, because SI had recently released a new ambient-light-rejection screen product: Slate®. Designed to meet SI’s goal of bringing two-piece projection to any environment, anywhere, Slate® was developed using what SI had learned from the creation of Black Diamond®, but could be manufactured at far lower cost. Most important, Slate® was a much more forgiving material that could be rolled up tighter and stretched out – a must for a screen that would need to occupy as little space as possible when not in use. After seeing a demonstration of Slate® at SI’s world (now galactic) headquarters, NASA representatives fell in love with the material – all agreed that a Slate® screen would be the one to go into space.

The Mount

The projection screen’s material chosen, work could now begin on the design and how the screen would be assembled. The idea of using a motorized screen configuration for deployment was immediately tossed out because, well, it’s space – there would be no gravity available to pull the weight bar down when the screen was opened. An SI engineer with a degree in aerospace engineering – coworkers call him the SI Rocket Scientist – was familiar with a type of bungee cord developed specifically for and used by NASA. Using these bungees as the design’s center point, the team quickly came up with a screen that could be rolled out by hand and attached essentially anywhere and in any cabin of the ISS modules, at each of the screen’s four corners. Fully deployed, stainless steal “leashes” would extend out of the aluminum tubes on each end of the screen, and attach to bungees which could then be secured to various locations inside the modules; for storage, they would neatly retract back into the tubes, leaving no excess cabling visible. The entire assemblage could then be stored in a larger tube with a corkscrew-style cap and shoulder strap, for easy transport in zero-g.

It functions somewhat similar to the way a motorized screen rolls out, but that’s where the similarities end. It is unlike any screen we have ever manufactured, and unlike any screen that any company has ever manufactured.

— Robin Kampf, Quality Manager at SI

After the first prototype screen had been built, SI traveled to NASA’s mockup facilities in Houston, Texas. A projector manufacturer provided a new, 1080p laser projector for the project that uses a new laser light-source technology. Before the introduction of this new laser technology, the maximum lifetime of a projector’s bulb averaged about 3,000 hours. With a laser projector, a single bulb can produce zero image degradation for up to 30,000 hours, or about 3.4 years of constant use – truly stunning. As SI deployed the screen and attached its four corners to the ISS module to display a 65-inch image floating in mid-air, the excitement among those present was palpable. It was a glimpse of what would become the first man-cave in space – a remarkable achievement. The NASA team finally decided that using one of the mounting arms already in place for crewmembers’ laptops would work perfectly for placing the projector. This gave the screen plenty of throw distance, and securing the projector to the mount with one of NASA’s Velcro strips would be a piece of cake.

Seeing the screen “floating” in the ISS module, NASA’s main concern was now the particles of various materials – foods, liquids, and other things – that would undoubtedly come into contact with the deployed screen. They wanted to ensure that the screen would be easy to clean and resist stains. Slate® passed these tests, too, with flying colors – cleaning the screen is as simple as wiping down its surface with a microfiber cloth. If the removal of larger particles is required, purified water – plentiful aboard the ISS – could even be used.

Start Countdown

Screen Innovations’ space screens traveled to the International Space Station aboard SpaceX 6 on April 14, 2015, to taking residence in their forever home among the stars. “Working with NASA has been a dream come true,” said Ryan Gustafson. “But even though they are such a high-profile client, they received the same passion and innovation that we put into every product we make.”

Here’s to NASA, and to the first man-cave among the stars – the sky is no longer the limit.

COMMERCIAL

COMMERCIAL

Great Blog! Thanks for sharing.